Water well systems are essential to various sectors, from municipal and agricultural to industrial and emergency applications. Traditional water well systems have long relied on rigid steel and plastic pipes, often in jointed segments. However, these systems present challenges: installation difficulties, the need for complex connections, vulnerability to corrosion, and high maintenance requirements. In response to these issues, Sterling Hose, Reel & Supply, LLC, is proud to introduce Sterling Secure Flow Hose for Wells—a revolutionary, flexible hose solution designed to simplify water well setups while delivering unmatched durability, efficiency, and cost savings. Drawing on the advanced technology and insights from high-performance hoses in the industry, Sterling Secure Flow Hose for Wells is crafted to meet the most demanding well applications.

Sterling Secure Flow Hose for Wells is engineered for flexibility and strength, transforming how water wells are established and maintained. Unlike traditional steel and plastic pipes, Sterling Secure Flow Hose for Wells one-piece design and superior materials offer seamless water flow, reduced energy costs, and an easier installation process.

Sterling Secure Flow Hose for Wells is designed with ease of installation as a priority. Unlike jointed pipes that require numerous connections, heavy equipment, and a crew to install, Sterling Secure Flow Hose for Wells offers a continuous, flexible hose that can be deployed quickly by a small team or even a single individual in smaller applications. This flexibility allows for easy adaptation to different well configurations, and the hose can be installed in one piece from surface to depth, significantly reducing the time and labor required for setup.

Streamlined Setup: With traditional jointed pipes, installation is often complex, requiring time-intensive alignment and sealing of individual segments. Sterling Secure Flow Hose for Wells single-piece hose eliminates the need for pipe joints, streamlining installation and reducing the chance of human error.

Adaptability: Sterling Secure Flow Hose for Wells flexible structure conforms to well contours, ensuring efficient water delivery without the need for rigid sections that can be difficult to fit in unconventional well designs.

Constructed from high-tensile synthetic fibers woven into advanced polymer layers, Sterling Secure Flow Hose for Wells is designed to withstand the challenges of well environments. It resists abrasions, corrosion, and UV exposure, offering a much longer service life than traditional steel or plastic piping, which are prone to rust, chemical degradation, and material fatigue.

Abrasion Resistance: The materials used in Sterling Secure Flow Hose for Wells are abrasion-resistant, allowing it to perform reliably even when in contact with rough surfaces within wells. This reduces wear over time and minimizes replacement needs.

Corrosion Resistance: Traditional metal pipes are highly susceptible to corrosion, especially when exposed to varying pH levels or high-mineral content in groundwater. Sterling Secure Flow Hose for Wells non-corrosive materials ensure a longer life in both acidic and alkaline water conditions, making it an excellent choice for wells in diverse geographical locations.

Sterling Secure Flow Hose for Wells features an ultra-smooth internal surface that minimizes friction losses. This design allows for greater water flow efficiency, improving pump performance and reducing the energy required to transport water from the well. By minimizing friction within the hose, Sterling Secure Flow Hose for Wells not only helps reduce energy consumption but also lowers operational costs over the lifetime of the well.

Improved Pumping Efficiency: With lower friction and a smoother water path, pumps do not need to work as hard to deliver the same volume of water, reducing wear on pumping equipment and extending its lifespan.

Reduced Power Consumption: Sterling Secure Flow Hose for Wells efficient flow characteristics reduce energy demand, leading to lower electricity or fuel costs for well owners—a significant advantage for high-usage agricultural and industrial wells.

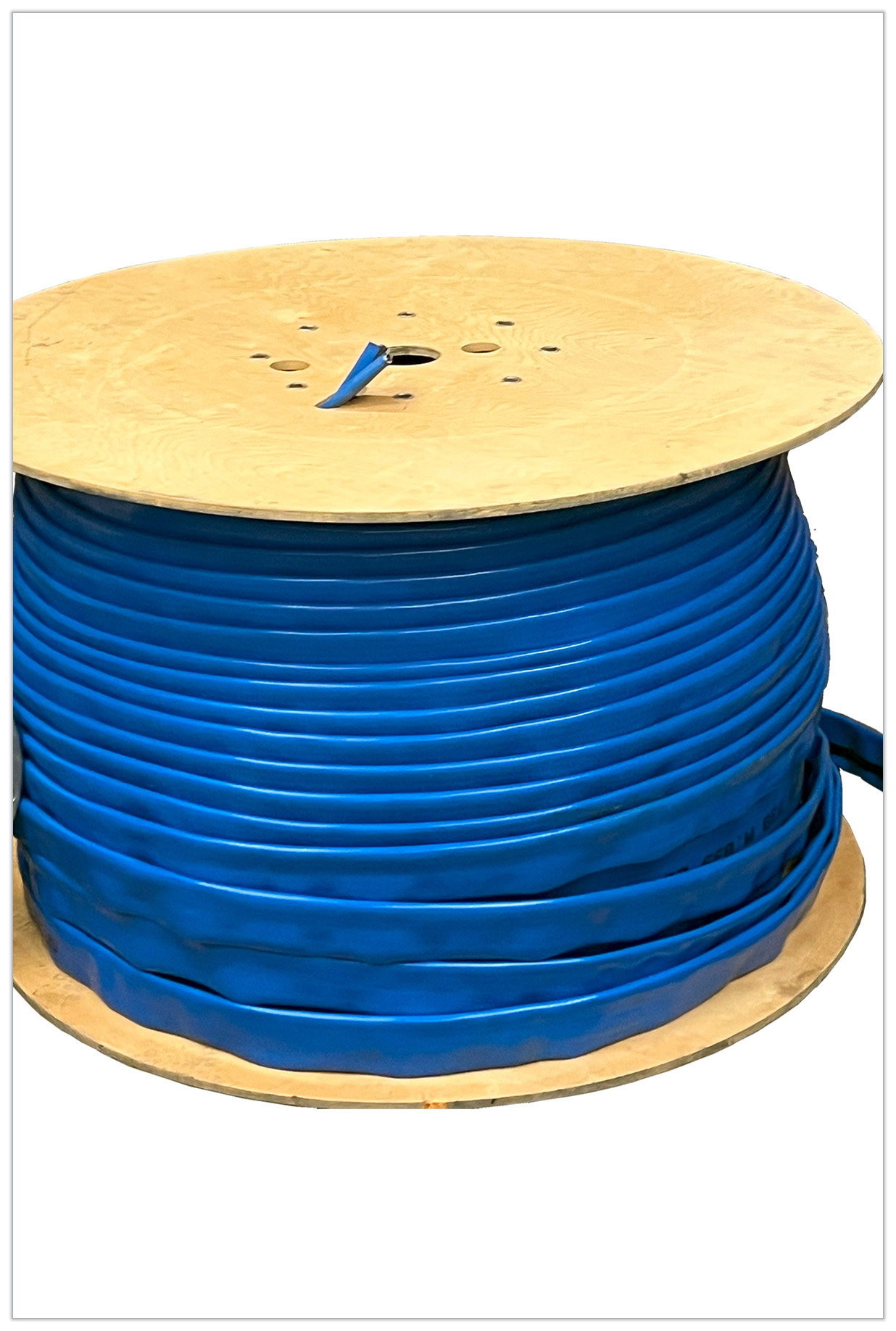

Weighing significantly less than steel and plastic pipes, Sterling Secure Flow Hose for Wells offers easy handling, especially in remote or hard-to-reach locations. Its compact, rollable design allows for straightforward transportation and storage, requiring less space and fewer logistical considerations than traditional pipe sections. This portability makes it especially advantageous in scenarios requiring rapid deployment or frequent relocation.

Compact Storage: The rollable nature of Sterling Secure Flow Hose for Wells allows it to be stored compactly, unlike traditional pipes which demand significant storage space and careful handling.

Ideal for Remote Wells: For well systems in remote or hard-to-access locations, transporting and installing jointed pipes can be logistically challenging and costly. Sterling Secure Flow Hose for Wells lightweight construction eases transport and reduces the need for heavy machinery, making it perfect for isolated setups.

The materials used in Sterling Secure Flow Hose for Wells provide robust chemical resistance, allowing the hose to withstand exposure to harsh chemicals, varying pH levels, and potentially contaminating substances in the groundwater. Unlike steel pipes that rust or plastic pipes that degrade under chemical exposure, Sterling Secure Flow Hose for Wells remains unaffected, ensuring clean water delivery and consistent performance.

Adaptability to Diverse Water Conditions: From saline to acidic water, Sterling Secure Flow Hose for Wells can handle various water types without compromising its integrity. This versatility makes it an ideal solution for diverse locations and applications.

Reduced Contamination Risks: Sterling Secure Flow Hose for Wells continuous, joint-free design eliminates the risk of leaks and contamination at connection points, ensuring safer and cleaner water delivery.

With Sterling Secure Flow Hose for Wells, initial setup, operational, and maintenance costs are minimized. The durable, corrosion-resistant materials extend the hose’s lifespan, reducing the need for frequent repairs or replacements. Additionally, the smooth internal design means less buildup, ensuring consistent flow and performance with minimal maintenance.

Reduced Installation Costs: The simplified installation process reduces the need for specialized labor and equipment, offering immediate savings.

Low Maintenance Requirements: Thanks to its durable construction and resistance to wear and corrosion, Sterling Secure Flow Hose for Wells requires minimal upkeep, saving time and resources over the long term.

_________________________________________________________________________________________________________________________

Prone to Corrosion: Steel is vulnerable to rust, especially in wells with high mineral or saline water, leading to contamination risks and pipe degradation.

Heavy and Rigid: Steel is difficult to transport, install, and adjust, requiring a full crew and heavy machinery for setup.

High Maintenance Costs: Frequent replacements and repairs due to rust and degradation make steel a costly choice in the long run.

Limited Durability: While lighter than steel, plastic pipes can crack or degrade under high pressures, limiting their use in deep wells or demanding conditions.

Chemical Vulnerability: Exposure to various chemicals in groundwater can cause plastic to deteriorate, leading to leaks and contamination.

Joint-Dependent: Like steel, plastic pipes require joints, creating potential points of weakness and leakage over time.

________________________________________________________________________________________________________________________

Sterling Secure Flow Hose for Wells provides municipalities and residential areas with a clean, durable, and efficient water delivery system. The hose’s chemical resistance and non-corrosive properties make it ideal for urban and rural water supplies, ensuring safe, contamination-free drinking water.

In agricultural settings, where water demand is high, Sterling Secure Flow Hose for Wells smooth water flow and low friction are beneficial for large-scale irrigation. It’s easy installation and removal capabilities make it a top choice for farms, allowing seasonal adjustments without high labor or equipment costs.

Industries and mining operations demand durable and reliable water systems. Sterling Secure Flow Hose for Wells resilience to abrasives, chemicals, and high pressures makes it ideal for these rugged environments. The hose can transport water as well as slurry and other fluids commonly needed in industrial and mining processes.

In disaster relief or temporary operations where rapid water access is crucial, Sterling Secure Flow Hose for Wells offers unmatched portability and ease of setup. Its lightweight design and flexibility make it an excellent choice for temporary installations in remote areas.

Sterling Secure Flow Hose for Wells brings a new level of efficiency, durability, and cost savings to water well systems. By leveraging advanced materials and a joint-free, continuous design, we have created a product that eliminates the traditional drawbacks of steel and plastic piping. With Sterling Secure Flow Hose for Wells, you gain a system that’s quicker to install, longer-lasting, and requires minimal maintenance, making it the ideal solution for any water well application.

Our experience with water projects spans four generations and we apply this

knowledge and expertise to every project. We constantly introduce innovation that allows Sterling to provide quality products to a wide range of industries.

Sterling and their strong global supply chain provide superior lay-flat hose products and handling equipment to the world.

Sterling is based in Texas and trusted globally.

Designed by Sterling Hose, Reel & Supply. LLC. | © 2025 Copyright Sterling Hose, Reel & Supply, LLC. | Privacy Policy | Terms & Conditions